The Straganizer

A project for ME345: Automated Manufacturing

Introduction

The Straganizer project was a final project for BU’s ME345: Automated Manufacturing. The goal of the project is for students to create their own two-piece product for machining and assembly at BU’s Automated Manufacturing Design Lab. Groups have all the lab resources available for their use including two Haas Mini Mills, three UR5 robots, a RGV conveyor, and several stock polycarbonate and HDPE pieces. For me, this project was a great opportunity to learn more about Gibbscam and machining methods.

The Straganizer is a device meant to hold re-usable straws for storage and drying. Part of the project requirements are to make a product that benefits the greater community, so my group decided on a Straganizer to encourage more people to use re-usable straws.

Background

The BU ADML is a lab space in BU’s machine shop, EPIC. The ADML exists to expose students in the Automated Manufacturing class to real tools that are used in manufacturing systems, including robots, vision systems, PLC, mills, and control systems. There are three main stations in the ADML. Station 1 is the assembly station, featuring a UR5 robot named Rosie, an assembly vice, a squaring fixture, and a pallet buffer. The pallet buffer holds four RGV pallets that carry parts from station to station on the conveyor belt. When a pallet reaches its destination, a solenoid actuates to hold it in place, and the robot from the station can pick the pallet off the conveyor and put it into its pallet inventory. All the stations have a pallet buffer. Two stations are milling stations, both featuring a Haas Mini Mill, UR5 robot, a squaring fixture, and gravity stock feeders. The robots are able to service the mills, including loading stock from the gravity feeders, unloading milled parts, and moving pallets on and off the conveyor belt. The last station is an inspection station, featuring a camera to observe pallets as they pass by.

Design

The Original

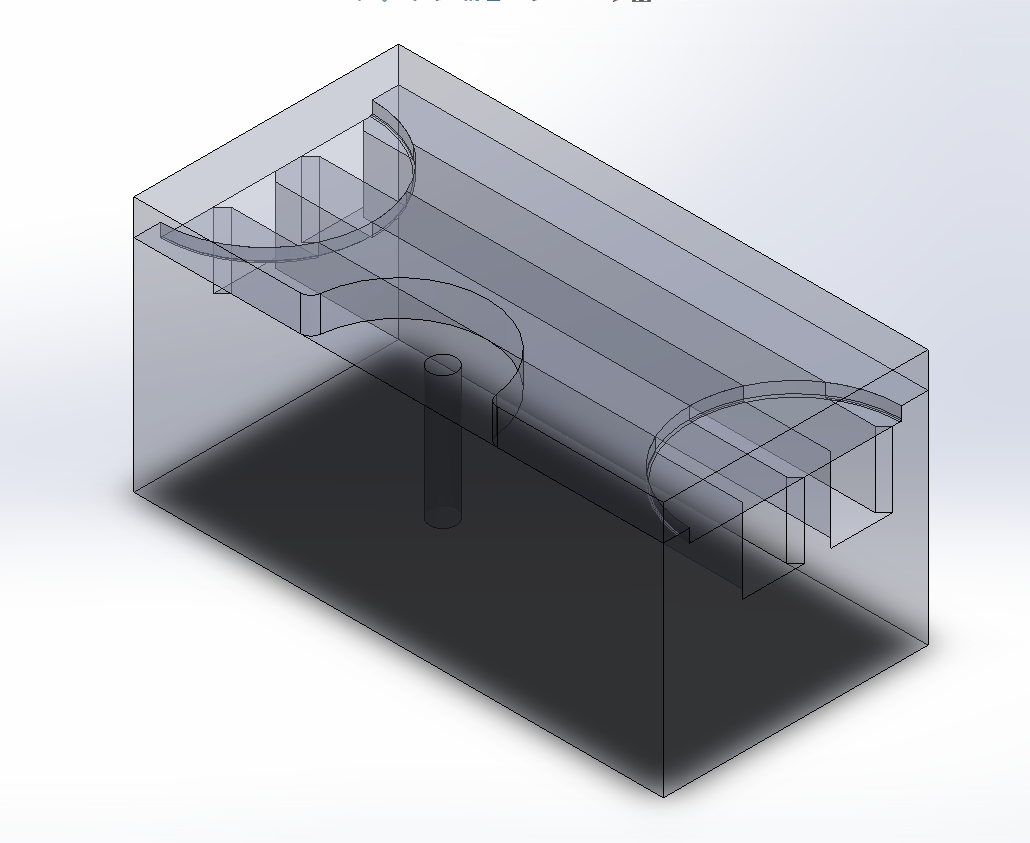

The original straganizer was constructed from 3x1.5x1.25” HDPE and 3x1.5x0.25” Polycarbonate. The two pieces, the body and the lid, snapped together via three pins. Part of the assignment requires that the robots are able to assemble the product, so chamfers are added to the edges of the pins and the holes to increase the locational tolerance on the assembly process. The exact position of the robot can only controlled down to a certain tolerance, so the chamfers help account for misalignment during assembly caused by slight positional inaccuracies from the robots. The straganizer has two main features, the straw holders and the cleaning device holder. The two channels in the body are for holding up to four regular sized straws. There is a also a hole in the top of the body for holding straw cleaning devices. The lid has a relief cut in it so that it won’t cover the hole for the cleaning devices when the Straganizer is assembled.

Second Generation

The whole purpose of this project was to create a product and then refine its manufacturing process to make it more efficient. What is more efficient in this case? In a manufacturing cell, there are a few basic principles that drive process improvements. Firstly, the fastest possible throughput of a manufacturing system is equal to the throughput of its slowest process (the bottleneck). In general, a good manufacturing system has a bottleneck throughput equal to market demand. Due to this principle, all the other machines in a manufacturing process should only be utilized enough to keep the bottleneck processes working as consistently as possible. In the case where it is necessary to speed up a production facility, it may be desired to increase the capacity of the bottleneck.

In the case of the Straganizer, our group decided to increase the throughput of our manufacturing process by speeding up our bottleneck process. To increase the throughput of our overall process, we made changes to the design that required less material to be removed from the body. This caused a decrease in the milling time, and increased the throughput of our bottleneck.

Instead of using pins to connect the two pieces, we changed our joining method to two snap fit surfaces on each end of the part. Instead of roughing out 0.25” of material off the top of our part now, we only had to remove two semicircular areas on each end. This design change resulted in an almost twofold improvement in process time.

Conclusion

The Straganizer was a valuable exercise and a fun project. My role on the team allowed me a lot of flexibility to play around with Gibbscam and get a strong understanding with how it works, and build familiarity with CAM techniques.